Ventilation of tunnels as a method for providing fresh air and exhausting gases from combustion in cars is very common. Even in metro tunnels where there are no combustion gases, the ventilation system is necessary in order to provide fresh air and also smoke evacuation in emergency conditions. There are different regulations for tunnel ventilation in different regions of the world. Different types of ventilation systems are also used regularly, but in the end, they all use two main types of fans, namely axial fans and jet fans. The basis of all the designs is the supply of fresh air from one part of the tunnel and its discharge from another part.

Jet fans in longitudinal systems by moving air from the air supply side to the discharge point cause the movement and discharge of pollution or smoke from the tunnel. In order to increase efficiency in the tunnel ventilation design, the amount of pollutants produced by cars or metro inside the tunnel should be calculated first. Then, having information such as the length of the tunnel and its conditions, he proceeded to choose the appropriate ventilation method.

These methods are:

- Natural ventilation

- Longitudinal ventilation through injection

- Semi-horizontal emptying system

- All width empyting system

- Ventilation of subway tunnels and...

In order to domesticate the supply of Tehran metro fans, this company has performed a functional test (type test) for fans with a diameter of 2240, 2000 and 2500 mm in the laboratory approved by AMCA outside the country. After completing these tests, the company has provided F250 exhaust fans in line 7 of Tehran Metro.

By using SES and FDS software, Bostanchi industrial group is able to design and model a complete ventilation system for metro lines and tunnels.

Examples of the tunnel ventilation system are presented below:

1. Natural ventilation

2. Natural ventilation with a central shaft

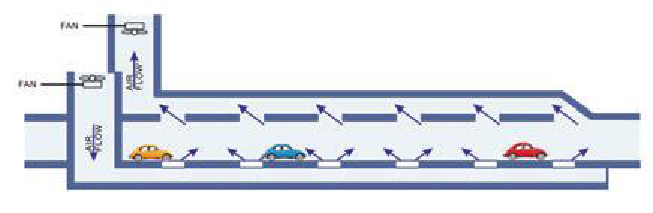

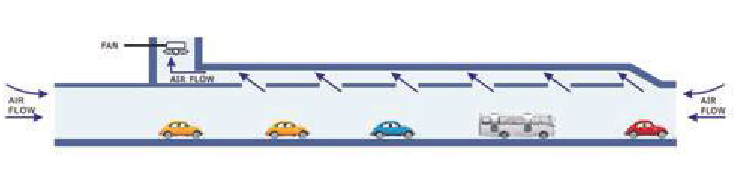

3. Longitudinal injection type ventilation

4. Longitudinal ventilation with a central discharge shaft

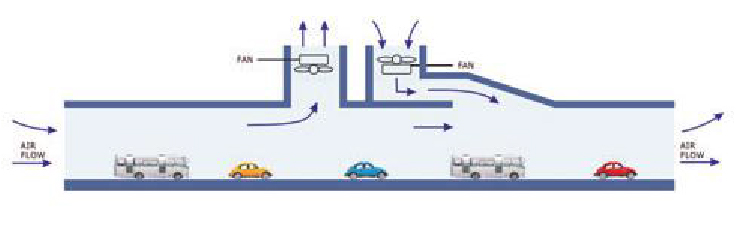

5. Longitudinal ventilation with central air supply and exhaust shafts

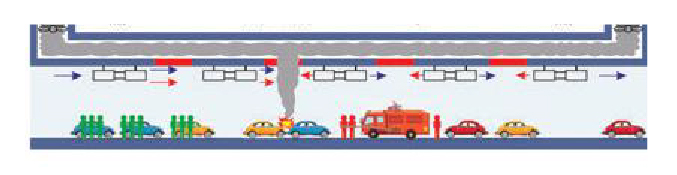

6. Longitudinal ventilation with point suction

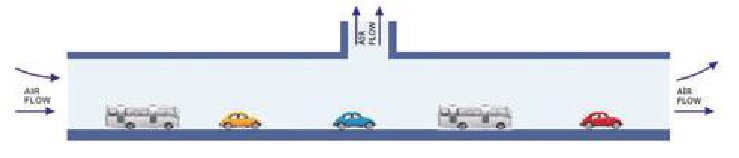

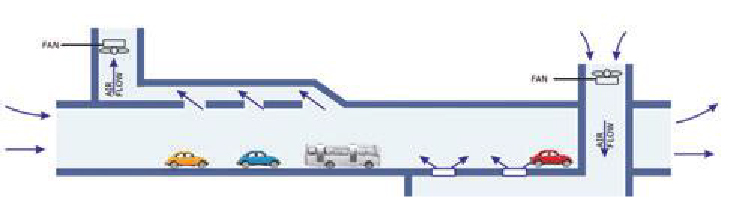

7. Semi-horizontal emptying system

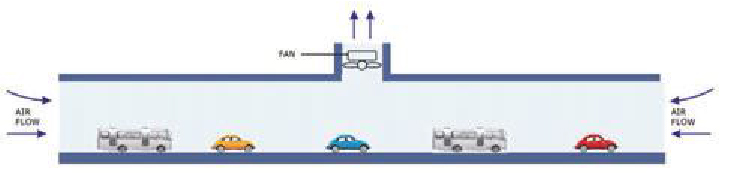

8. Semi-horizontal air supply system

9. Semi-transverse discharge system for equal supply and discharge

10. Full width system